Advantages

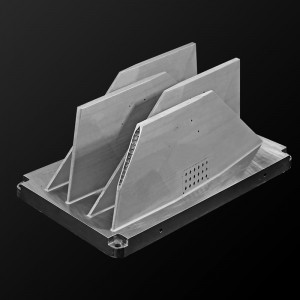

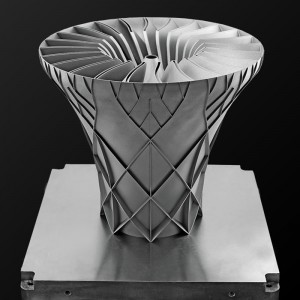

High temperature resistance

Excellent dimensional stability

High strength and accuracy

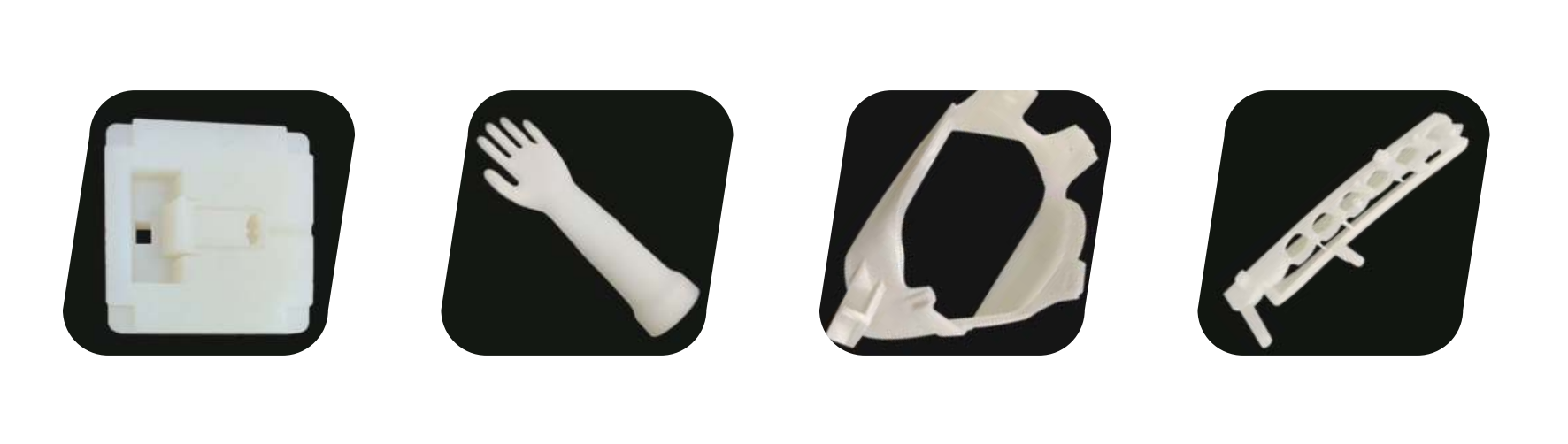

Ideal Applications

Prototypes need high-temp resistance

Quick mold

Technical Data-sheet

| Liquid Properties | Optical Properties | |||

| Appearance | Semi-translucent | Dp | 13.5 mJ/cm2 | [critical exposure] |

| Viscosity | 340 cps@30℃ | Ec | 0.115 mm | [slope of cure-depth vs. In (E) curve] |

| Density | 1.14 g/cm3 | Building layer thickness | 0.08-0.12 mm | |

| Mechanical properties | UV post curing | |||

| Test items | Test Methods | Numerical value | Test Methods | Numerical value |

| Tensile Strength | ASTMD 638 | 65MPa | GB/T1040.1-2006 | 71MPa |

| Elongation at break | ASTMD 638 | 3-5% | GB/T1040.1-2006 | 3-5% |

| Bending strength | ASTMD 790 | 110MPa | GB/ T9341-2008 | 115MPa |

| Flexural modulus | ASTMD 790 | 2720MPa | GB/ T9341-2008 | 2850MPa |

| Izod notched impact strength | ASTMD 256 | 20J/m | GB/T1843-2008 | 25J/m |

| Shore hardness | ASTMD 2240 | 87D | GB/T2411-2008 | 87D |

| Glass transition temperature | DMA, tan θ peak | 135℃ | ||

| Thermal expansion coefficient(25-50℃) | ASTME831-05 | 50 µ m/m℃ | GB/T1036-89 | 50 µ m/m℃ |

| Thermal expansion coefficient(50-100℃) | ASTME831-05 | 150 µ m/m℃ | GB/T1036-89 | 160 µ m/m℃ |

Recommended temperature for processing and storage of the above resin should be 18℃-25℃.